Our technical expertise

Autajon brings together all the technical expertise required for packaging and labeling: multi-technology printing, premium finishes, foil stamping, embossing, die cutting, quality control, and more. By continuously investing in the most advanced equipment, we guarantee high-precision packaging and exemplary industrial consistency across all our markets.

Expertise that guides your choices

At Autajon, our expertise guides every technical choice. From materials to technology, we recommend the best tailor-made solution for a reliable aesthetic result that is perfectly suited to your project.

Listening to and analyzing your needs

Every project developed with Autajon begins with a phase of listening to and analyzing your needs. We study your aesthetic, technical, and commercial objectives to define a truly customized solution. Nothing is preformatted: every package and label is designed based on your product, your constraints, and your vision.

The choice of materials

Whatever your project, we offer the most suitable materials for your labels, folding cartons, or rigid boxes. Our suppliers are rigorously audited and recognized for the quality of their materials. We favor European partners, such as forestry operators, for the cardboard used at our sites based in the European Union.

Cardboard substrates designed for reliability and shaping

Coated, uncoated, levels of whiteness, rigidity or mechanization options, weights, recycled, co-sourced or virgin materials: each cardboard is evaluated according to its performance in production, its aesthetic appearance, and your logistical constraints.

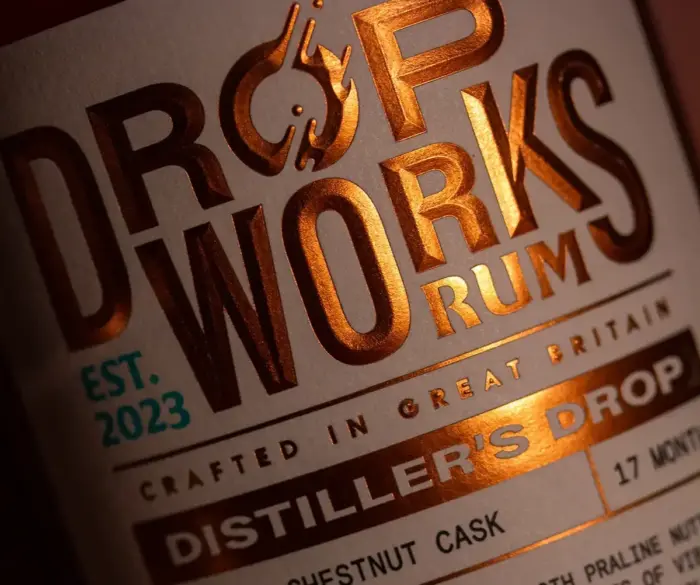

Label substrates adapted to each container

PP, PE, PET, coated or uncoated paper, recycled materials, co-sourced substrates made from barley or grape residues… We select the material based on the shape of your container, the humidity level, the expected lifespan, the desired level of transparency or opacity, and your graphic expectations.

The best technical platform

Each design, each material, and each finish requires precise configuration. We systematically identify the best combination of technologies and the best production site to guarantee faithful, consistent, and technically optimal results. Autajon’s role is to advise you and recommend the technical platform best suited to your project.

Validate each step before production

Before going into production, each project undergoes tests tailored to its intended use: verification of proper mechanization, durability and resistance tests, logistics tests (drops, abrasion, etc.), and adhesion checks for labels. This phase concludes with a BAT or “Bon à Tirer” (ready to print), which validates the final result and serves as a quality reference for the entire production run.

The goal is simple: to ensure that your packaging performs perfectly, from packaging to end use.

The art of bespoke tailoring

At Autajon, every project is unique. We draw on proven experience to continually enrich our expertise. Your needs are our starting point. Materials, techniques, finishes: every parameter is adjusted to create a solution that is truly 100% tailor-made.

Complete mastery of market technologies

Offset, flexography, screen printing, gravure printing, digital printing, or hybrid solutions: Autajon masters all printing processes to meet every requirement. This technological diversity allows us to adapt each process to the right project, optimize the result, and guarantee impeccable consistency for your labels, folding cartons, or rigid boxes.

Innovation in the service of precision

Recognized for over 10 years for our expertise in digital printing, we also offer combined solutions that combine several technologies on the same product. The result: total flexibility, richer designs, and expanded creative possibilities, always adapted to the expected quantity.

Our value-added techniques

Gilding

Hot & cold foil stamping

Gilding adds sparkle and sophistication thanks to precisely applied metallic films. Hot foil stamping offers a bold, textured finish, while cold foil stamping allows for very fine details and more varied effects. These techniques enhance the visibility and premium feel of the design.

Relief depths

Embossing & Stamping

Embossing creates a tactile relief by playing on volumes, while stamping applies a recessed effect. These finishes add depth, structure key areas, and enhance the graphic elements of a label or packaging. We can also combine them to create a multi-level relief, a beautiful enhancement without adding material.

Textures and light effects

Special varnishes & tactile effects

Relief varnishes, selective varnishes, soft-touch, satin, glossy, or sandblasted: each varnish can be used to highlight a specific area or change the feel of the print. They play on contrasts and reinforce visual identity. They allow you to play with light and sometimes even create “easter eggs”: varnishes that react to UV light, are luminescent, or reveal themselves when heated. The possibilities are endless.

Metallization

Metallic effects

Metallization provides uniform or targeted shine to enhance graphics, flat colors, or decorative elements. Thanks to our cutting-edge technologies, we reproduce intense metallic finishes, from chrome to gold to holographic effects. This technique produces premium finishes that are perfect for enhancing the visual impact and perceived quality of your labels, folding cartons, or rigid boxes.

Accuracy

Complexe die cuts

Thanks to high-precision cutting tools, it is possible to create custom shapes, openings, perforations, or cutouts. These personalized effects reinforce brand recognition and provide a unique visual signature. These techniques can also make your packaging interactive: an opening to touch the product. It can also be a hollowed-out label that plays with the color of your products to complement the label’s design.

Protection

Technical laminations

Matte, glossy, soft-touch, or textured, lamination protects labels and cardboard while enhancing their appearance. It improves resistance to moisture, friction, and handling, while adding a high-end finish. We offer soft-touch lamination, often referred to as a peach skin effect, which provides a velvety, high-end feel.

Premium details

Rare finishes that make all the difference

Certain finishes, more discreet but highly sophisticated, add a unique signature to your packaging. These include edge coating, which colors and enhances the edges of your folding cartons for a flawless finish. Another option is the integration of glitter, with or without PET, into the design to add a subtle, high-end sparkle.

These premium details, less known to the general public but highly appreciated by brands, reinforce the perception of quality and differentiate your special editions or iconic creations. Perfect for promoting your range while remaining perfectly consistent with your visual identity.

Quality and control: the Autajon requirement

Each project is subject to rigorous monitoring to ensure consistent and reliable results, from prototype to final product. Our teams apply high standards at every stage to ensure the safety of your packaging and labels.

Continuous monitoring at every stage

Automated inspection and quality control

Full traceability

Certified processes

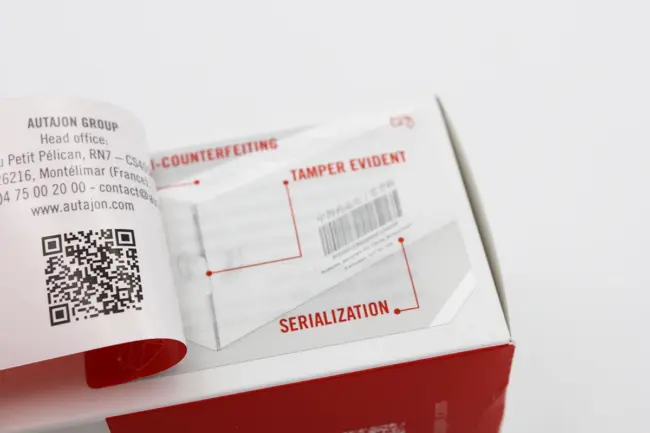

Security & traceability

With our long-standing experience in the pharmaceutical sector, Autajon has mastered all packaging security and identification techniques. We know that the security and traceability of your products are paramount: every consumer must be able to verify the authenticity and integrity of products.

Advanced traceability and identification

We offer a comprehensive range of solutions: tamper-evident closures, tamper-evident seals, child-resistant or ergonomic systems for the elderly, unit traceability and serialization, as well as identification via QR codes, DataMatrix, unit codes, or advanced technologies such as Signoptic, which checks the unique fingerprint of each carton.

Tamper-proof solutions

Devices that guarantee product integrity until first opening. They protect consumers by allowing them to check that the product has not already been opened.

Anti-counterfeiting technology

Special inks or invisible markings to protect your products from counterfeiting.

Traceability and serialization

Each product can be identified via QR Code, DataMatrix, unit code, RFID chip, or Signoptic for complete tracking throughout the chain.

Special unboxing

Child-resistant or ergonomic opening systems for the elderly, combining safety and practicality.

CAD & Graphic Design Studio

A unique synergy between engineering and graphic creativity.

CAD engineering: custom-made shapes

Our CAD engineers design custom-made folding cartons and rigid boxes, choosing the right cardboard, the ideal weight, and the appropriate mechanization. Each shape is tested for strength, openings, and functionality, whether it is a classic model or an original shape and opening.

Graphic design studio: creativity and technical expertise

Our graphic design studios, staffed by artists trained in fine arts and experts in the world of wine, design labels that reflect the identity of each winemaker. Their in-depth knowledge of printing techniques and industrial constraints guarantees unique, aesthetic, and perfectly feasible creations.

Structural development

Models & Prototyping

Graphic design